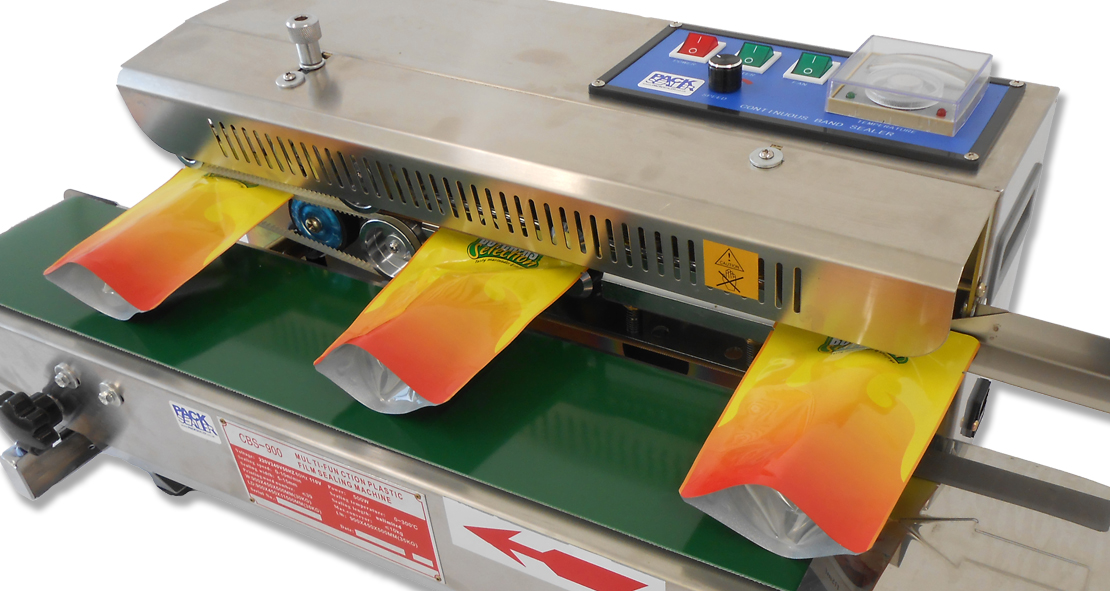

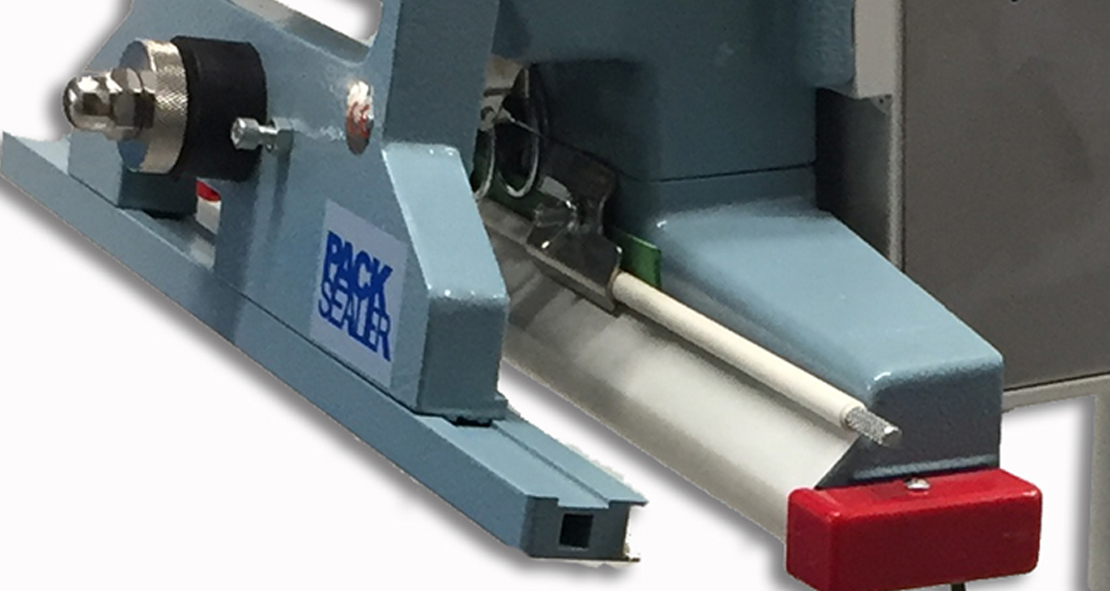

PackSealer offer a comprehensive range of Hand Operated Plastic Bag Heat Sealers, Foot Pedal Operated Heat Sealers and Vacuum Sealer equipment to meet pretty much any application. Our equipment is of the highest quality and the best price, customer service is a major priority for PackSealer.

you PACK it – we SEAL it

PackSealer for Heat Sealers and Packaging Equipment

You can buy PackSealer heat sealers and packaging equipment without any fuss through our online shop. Pack Sealer supply British made Hulme Martin Heat Sealing equipment, Star Universal Specialist Heat Sealers, European manufactured Audion Heat Sealers, Lavezzini Vacuum Sealers and Optimax Packaging Equipment too. Making a purchase could not be easier. Just browse our PackSealer store, and add any items that you wish to buy into the shopping cart. After you have finished your selection, click on ‘Checkout’ and you will be asked for a few details that we need to be able to complete the order.

For orders outside of mainland UK delivery times may be longer and maybe subject to import charges.

Many of the Audion and Lavezzini machines and spares are shipped directly from outside of the UK so additional import charges may apply.

PackSealer – You Pack it We Seal it! watch the Video: https://youtu.be/_4aNrKbcvWM

Need Help?

Featured Products

Top Brands

Loading...