- Description

- Brand

- Additional information

Description

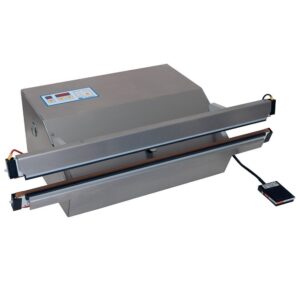

This is a bench mounted or free standing probe type external vacuum sealer.

If you are sealing modern barrier materials such as foils and nylon laminates up to 900mm in width this is the machine with both jaws heated.

Seal Length options 500mm 600mm 750mm 900mm

Seal Width 6mm standard. Optional 2.5mm, 9mm, 12.5mm and 20mm

Manual and automatic vacuum clamp jaws are available with either solenoid or pneumatic sealing jaw operation. A range of vacuum pumps are available between 6 and 15m cube/hr. The vacuum cycle can be manual, automatically timed or programmed to a preset level. As your bag is not placed inside a chamber there is no real limit to the maximum product length.

External, nozzle or probe type vacuum sealers are ideal for larger plastic bags. These are more suitable for dry products but not for liquids.

This vacuum sealer can be finished in powder coated mild steel. Options include a support tray and gas flush.

For food or for more corrosive environments we can offer a stainless steel finish.

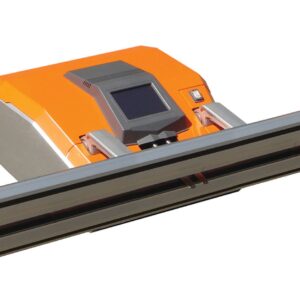

The Star vacuum sealer 106 is available with four different seal cycle controllers:

The MkVI controller offers weld and cool control to the nearest 1/10th of a second and has a built in programme to help counteract the effects of heat build-up during frequent sealing. The MkVI C has weld and cool control to the nearest °C. Adjustment can be made by the keypad with an LCD readout of the settings. The keys can also be locked to prevent unauthorised alteration.

The Star ARTICS controller and Medical controller are suitable where more accurate controls are required, the also allow the element to ramp up to a weld temperature and be held for a time. Cooling time or temperature and element preheat are also included. This allows for a perfect weld to be achieved every cycle. All settings are password protected and the board allows up to 8 different sets of parameters to be programmed. Alarm parameters can be set to give operational tolerances; seal cycle data storage is available with a Medical controller.

Made in the United Kingdom by Star.

Please contact PackSealer to confirm the delivery time of the S106 VacPacker model as these are normally made to order.

Available options:

- Heavy Duty Shrouded Footswitch

- Heavy Duty Air Footswitch

- Stainless Steel Finish

- Remove TL6 vacuum pump and put 3 pin socket in

- Upgrade to TL10 vacuum pump (10 m³/h) (Needs pneumatic probe)

- Upgrade to TL15 vacuum pump (15 m³/h) (Needs pneumatic probe)

- Upgrade to Star MkVI C Controller

- Star ARTICS Seal Cycle Controller

- Star Medical Seal Cycle Controller

- Pneumatic Probe (100mm adjustment, solenoid/pneumatic machine)

- Gas flushing automatic timed/manual push button

- Pneumatic Jaw Operation

- Parallel Weld for Single Transformer (Pneumatic probe only)

- 115V Operation

Read our article on Vacuum Sealers:

Also check out the Star 66 S66

https://www.packsealer.co.uk/heat-sealers/star-66-vertical-heat-sealer/

All Star heat sealers can be fitted with a range of control options.

The process of impulse heat sealing involves heating the material being sealed beyond its melt point, pressing the two layers together then cooling it to produce a solid seal. The more control over the weld temperature, weld time and cooling temperature the better and more consistent the weld produced. Welds produced without enough heat or time can look sealed but may separate if pressure is applied. Welds produced without enough cooling appear to be molten and are weaker than a weld that has been allowed to cool under pressure properly. Welds produced without enough pressure may separate easily or appear molten even if enough heat and cool are used. To prevent unauthorised alteration of the sealing parameters the MkVI and MkVI C controllers come complete with a built in keypad lock. The Star ARTICS and Medical controllers have multi level pass code protection to aid with validation process control.

Star bag sealers and vacuum sealers offer you the option of four different controllers which are available on most of our machine range. The MkVI controller is fitted as standard (with the exception of the Medical Vacuum Sealer). Like most impulse sealers, this uses a weld and cool time (the element heats up for the weld time and is off for the cool time). Unlike most other heat sealers the weld and cool times are displayed to the nearest 1/10th of a second and the controller includes a heat build up compensation program.

The MkVI C allows the weld and cool temperature to be set. This allows it to automatically adjust for problems with heat build up. The element heats up until it reaches the weld temperature, then is turned off. The jaws open once the cool temperature is reached, allowing the material being sealed to set properly before release.

The Star ARTICS controller takes the level of control even further. The heating element heats up to the weld temperature and holds the set temperature for a set time. It then cools the element to a temperature or time, dependent on application. There is also a preheat option so the machine heats the element to a set temperature when not in use. When fitted to a Medical Vacuum machine the ARTICS controller also controls the vacuum and gas flush times.

The Star Medical controller has the same features as the ARTICS controller, with the additional features of measuring and controlling the weld pressure, independent second temperature control (if a second element is used) and seal cycle data storage for upload to a computer. When fitted to the Medical Vacuum Sealer the Star Medical controller also measures and controls the vacuum and gas flush levels in mBar.

Star MkVI Controller

Fitted as standard to most machines

Weld and cool timed to the nearest 1/10th of a second

Membrane keypad with LCD display and LED indicators

Keypad can be locked to prevent unauthorised alteration

Programmable heat compensation built in to reduce weld time during rapid and repeated operation

Built in adjustable jaws closing timeout alarm for operator safety

Coded error reporting on the display

Power to the elements and jaws closed actuator cut in any error state

MkVI C Controller

Optional on most machines

Weld and cool temperatures measured to the nearest 1°C

Membrane keypad with LCD display and LED indicators

Keypad can be locked to prevent unauthorised alteration

Automatically compensates for heat build up during rapid and repeated operation

Built in adjustable jaws closing timeout alarm for operator safety

Coded error reporting on the display

Power to the elements and jaws closed actuator cut in any error state

Star ARTICS Controller (Advanced Real Time Impulse Control System)

Optional on most machines

Weld and cool temperatures measured to the nearest 1°C and 1/10th of a second

Preheat temperature for the element when not in use

Membrane keypad with Multi Line LCD display and LED indicators

All settings protected with multi-level passwords

Alarms can be set for temperature deviation during the weld cycle

Built in adjustable jaws closing timeout alarm for operator safety

Timed vacuum and gas flush cycle on Medical Vacuum Sealer

Alphanumeric error reporting on the display with audible signal

Power to the elements and jaws closed actuator cut in any error state

Up to 10 preset programs can be stored with an alphanumeric name

Built in batch counter

Star Medical Controller

Optional on pneumatically operated machines

The Star Medical controller comes with all the features of the ARTICS controller plus:

Twin channel temperature control for a second element

Sealing pressure monitoring with alarm parameters

Weld pressure can be controlled electronically

Vacuum and gas flush level monitored in mBar

Seal cycle data recording and stored for upload onto a computer

Brand

Star Universal

Star Universal British Heat Sealers

Star Universal manufacture heavy duty bag sealers, vacuum sealers and specialised industrial heat sealers in the UK. The range of Star Universal industrial heat sealers, sack sealers and vacuum sealers offers flexibility and reliability whether you are sealing polyethylene bags, medical pouches, laminate vacuum pouches or foil bags. The UK factory ensure the highest of standards and quality assured impulse heat sealers. Many sealers are built to order so it is worth checking first with PackSealer to confirm the availability and delivery lead time. Star Universal have been designing and manufacturing industrial heat sealers for over 40 years. They can produce custom and special purpose heat sealing machinery meeting client requirements across a wide range of industries. If you need a modification to one of the standard heat sealers or something more unusual, PackSealer will work with you and Star to produce a solution based on Star's proven heat sealing equipment. Quality and consistency of seal are the qualities of Star Universal heat sealing machines. Heat compensation technology helps every seal to be the same high standard, even during repeated cycling of the heat sealer. Star’s Mk.VI C, Medical and ARTICS controllers have a heat sensor inserted into the sealing jaws giving unrivalled control of sealing temperature. Star also offer a fully validatable Medical sealer which has been approved by the medical and pharmaceutical sectors. Star Universal industrial bag sealers, sack sealers and vacuum sealers have a well-deserved reputation for durability and reliability. Full spares and service support for the range of bag sealing machines, direct from PackSealer. Please note that Star Universal heat sealers may have to be made to order and are not stocked by PACKSEALER. Please check with PACKSEALER for delivery information prior to ordering.

Additional information

| Weight | 100 kg |

|---|---|

| Jaw Width | |

| Finish | |

| Bag Material | Heavy Duty Thermoplastic, Medium Duty Thermoplastic, Metalised Laminate |

| Capacity | |

| Feature | |

| Seal Length | |

| Seal Width | |

| Sealer Type |