- Description

- Brand

- Additional information

Description

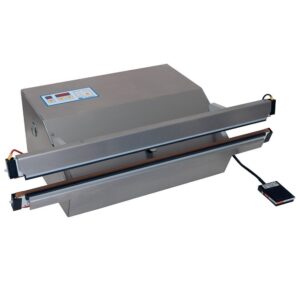

ATEX Vacuum Heat Sealer: an explosion proof steam impulse heat sealer for packaging explosion sensitive products in hazardous environments.

Audion Power ATEX Heat Sealer AEX (explosion proof)

A unique steam-driven impulse of sealer enabling bags to be sealed without electrical power supply. Instead, it uses pressurised steam to heat the sealing bars, hereby avoiding risk of ignition. Available in 610mm, 800mm or 1000mm seal length.

Safe operation:

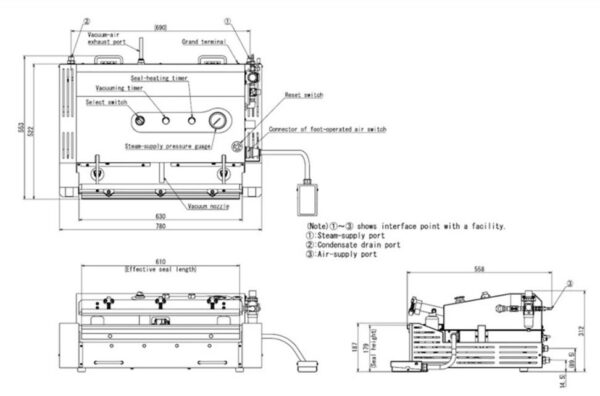

This industrial ATEX steam sealer is equipped with an Air PLC controller on which you easily set the process variables. The sealing process is started by pressing the foot pedal, after which pressurized steam is supplied to the sealing bar. During the sealing process, the steam is brought under pressure in the sealing tube on the lower sealing bar. The sealing temperature corresponds to the pressure of the steam supply, ensure your package is safely sealed with a strong 8mm seal.

Optimised workflow:

The Audion Power Sealer AEX optimises your packaging process, as products no longer need to be moved from the hazardous area to a safe zone for packing, but can be safely packed at the production site, reducing the required workspace saving valuable production time.

Customised packaging solution:

This Audion packaging machine is configurable as “sealing-only’ or vacuum sealer and as table top model or mounted on a convenient mobile support.

In Summary:

- ATEX rated

- Explosion-proof steam powered sealer operating without electric supply

- Available with or without vacuum system

- Easy to operate Air PLC controller (seal time, vacuum time)

- Convenient foot operation

- Configurable with optional support

On-site preparations required for your Power Sealer AEX explosion proof steam heat sealer

Before you can install your steam impulse sealer and benefit from an explosion-proof packaging solution, please take into account this steam sealer requires the following systems to properly function:

- Steam pressure regulator – To adjust the pressure supply of pressurized steam to the sealer.

- Pressure gauge – To check the pressure of pressurized steam at the interface point.

- Steam separator to collect residual moisture

- Steam supply valve – To stop the steam supply after a sealing cycle.

- Bypass valve – To dispose of initial air and water left from the previous operation inside the piping and drain, etc.

- Safety valve – Needed when primary steam pressure is more than 1.0mPa.

Should you do not meet the above requirements, please contact our sales department for customised advice and available solutions.

Note: Steam generators need to be installed outside the hazardous environment.

Brand

Audion

Audion Packaging Machines are high quality European made packaging machines with a worldwide service network.

With Audion you have a choice of packaging machines that meet your production requirements. The extensive range of machines covers a large packaging need. Audion Elektro specialise in design and development and manufacture of packaging machinery for the high-end packaging industry. Audion Packaging Machines are sold worldwide and pack everything; from medical, industrial parts to food. Audion Elektro manufacture high quality products for every market, from industrial to retail, standard or custom made, Audion develop a solution for your packaging challenges. Not only for today, but also for the future.Audion Packing Machines:

- Table top heat sealers

- Medical / pharmaceutical / high tech packaging

- Vacuum packing

- Automatic packaging

- Shrink packaging

- Rotary / Band sealers

- Tray sealers

- Packaging material – Consumables

- Packaging machines for E-commerce

Additional information

| Weight | 50 kg |

|---|---|

| Bag Material | Heavy Duty Thermoplastic, Light Duty Thermoplastic, Medium Duty Thermoplastic, Metalised Laminate |

| Capacity | |

| Feature | |

| Seal Length | |

| Seal Width | |

| Sealer Type |