- Description

- Brand

Description

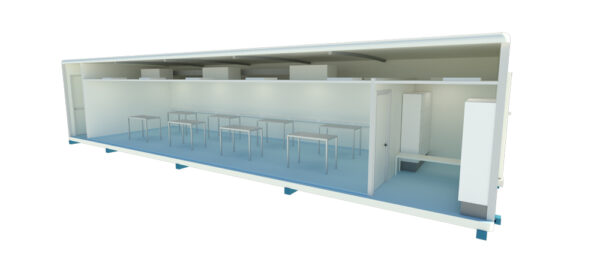

Modular Food Safe Room and Ambient, Chilled and Hygienic control solutions for food production, preparation and packing.

Portable Walk In Food Safe room linked to an existing building providing an alternative option to the traditional internal ‘fit-out’ kitchen market. When internal space is at a premium, a mobile food safe room can provide the solution; sited where space is created not necessarily where it needs to be.

The modular design can address your challenges when you require a clean room for a limited timespan a single modular cleanroom solution can be upgraded or added to quickly. Cost effective solution for bringing a process in-house with our modular cleanroom rental complex.

Used in the food and drink industries where hygiene is a priority.

Modular FoodSafe Room (MFSR’s)

- Mobile / Portable

- Fully self-contained

- Internally configured bespoke design

- Temperature / humidity control

- Antechamber / changing area

- Interlocking doors

Services & products

- Modular Food Safe Rooms (MFSR’s) an innovative modular plug & play design; where restrictions on space & flexibility is key

- Modular construction

- Segregation rooms for product trials, R&D, packaging & production runs

- Qualification, Validation & Compliance

Working with SiGum offering complementary products & services; high quality, reliable, specialist temperature control solutions.

What are Modular Food Safe Rooms?

Modular Food Safe Rooms are controlled environments delivered finished, sited externally and linked to your existing facility where you want the hygenic environment.

They come with a range of features and capabilities that are most often favoured by manufacturers and businesses conducting scientific research.

The features of Modular Mobile Clean rooms include:

- Controlled Environments. Each module of our Modular Cleanrooms is capable of providing a controlled environment that helps to prevent contamination from dust or airborne microbes. This adds incredible cleanliness and is determined by the number of airborne particles within the air – specifically measuring particles larger than 0.5um per cubic metre of air, plus the number of air changes needed per hour.

- Air Filtration Systems. We include the latest air filtration systems with our cleanrooms and ensure that your environment’s air is continually circulated and filtered, meaning there’s a lower level of internal pollutants.

- Temperature & Humidity Control. Our modular kitchen is used in multiple industries and markets, which is why it’s important for us to include temperature and humidity control – allowing you to store and manufacture products at extremely low and high temperatures.

- Modular Complex. We offer our Foodsafe rooms in modules as it allows our clients to add them to existing facilities and expand their operations. Plus, our portable walk-in rooms can easily be linked to the building externally, meaning you don’t have to compromise any internal space.

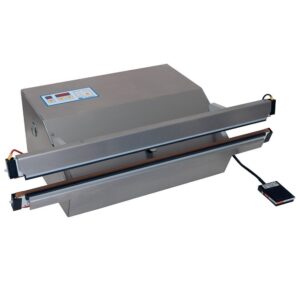

For Hygienic Cleanroom packaging machines see: Medical Sealers | Impulse Heat Sealers | Packsealer

Brand

PackSealer

You PACK it, We SEAL it!

SiGum